Here you'll find the most frequently asked questions about our products.

With which printer can DETAX 3D materials be printed?

The DETAX 3D materials can be used with DETAX-validated DLP LED printers. These are listed in the instructions for use for the respective materials. Currently, these are the open printing systems by Asiga, Microlay, MiiCraft, Rapidshape, Way2Production.

What does “open” or “closed” printing system mean?

With open printing systems, it is possible to use materials by various manufacturers. With closed printing systems, the material must be purchased from the specified source.

What is the difference between open and closed printing systems?

Apart from the fact that open printing systems allow using materials by different manufacturers, open printing systems also allow setting important machine parameters individually, or using and changing the corresponding specifications of the respective material manufacturers. These possibilities do not exist in the case of closed pressure systems. The material is supplied in special cartridges or is coded by an RFID chip, without which it is impossible to print. Here, too, there are no options for making adjustments to the material parameters, so the user is completely dependent on the printer manufacturer.

Which 3D material is suitable for which printer?

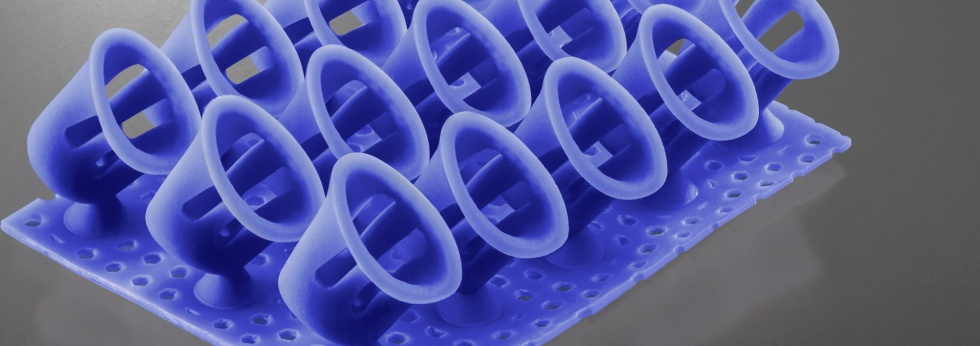

All DETAX 3D materials are matched to the corresponding wavelengths of

the projectors of the different printers.

In the audio sector, these are the luxaprint® UV andMedicalprint UV series for DLP LED printers with a wavelength of 385 nm (UV),

and the Freeprint® 405 series for DLP LED printers with a wavelength

of 405 nm.

In the dental sector, these are the Freeprint® UV series for

DLP LED printers with a wavelength of 385 nm (UV), and the Freeprint ®

405 series for DLP LED printers with a wavelength of 405 nm.

What is the difference between materials with a wavelength of 385 nm (UV) and 405 nm?

The materials must be precisely matched to the different wavelengths of the projectors so that they can be built quickly and precisely. The color quality of the materials with a wavelength of 385 nm is always better, especially in the case clear-transparent materials, since in the visible spectral range with a wavelength of 405 nm slightly colored additives have to be introduced into the material to enable precise building.

How and where can the Freeprint® 3D materials be obtained?

The Freeprint ® 3D materials for dental applications are available from all national and international dental dealers. You can find a dental depot near you on the DETAX homepage www.detax.de in the section “DentalDivision/Partner/National or International”. For earmold applications, luxaprint®/medicalprint®/Freeprint® 3D resins can be purchased directly from DETAX or international distributors.

Can DETAX materials be processed with a laser printer (e.g. Formlabs) as well?

Formlabs printers are closed printing systems in which individual settings of the required material parameters are not possible.

How to obtain a biocompatible object after the printing process?

For this, the instructions for use must be followed exactly. The specified printers and their material parameters, the described post-processing [2 × 3 min in isopropanol (≥ 98 %), washing with ultrasound and if necessary drying for 30 min at approx. 40 °C) and the recommended post-exposure device (xenon flash unit with protective gas (nitrogen)] must be adhered to meticulously.

What post-exposure devices can be used?

A Xenon flash unit with inert gas (nitrogen) must be used. The exposure time depends on the material and can be read in the respective instructions for use. Standard exposure devices with UV-A lamps or without inert gas do not conform to the requirements/performance for complete curing of the materials, and hence no guarantee can be given on the biocompatibility.

How to use an ultrasonic bath?

The ultrasonic bath must be filled with water. In this water bath then an additional solvent-resistant container filled with isopropanol is placed. The ultrasonic bath is never filled directly with isopropanol.

How long can the material be stored?

The material has a shelf life of two years in the original bottle. The storage conditions specified in the instructions for use must be taken into account during storage.

How can unused 3D material be stored after printing?

In

order not to impair the stability of the unused material, it is recommendable not

to fill the unused material back into the original bottle. Instead, the

material remaining in the trough should be covered with a lid and stored away

from light.

What has to be considered after a longer holding time of the materials?

Pigmented materials tend to segregate after a longer holding time. Therefore it is recommended to homogenize the material one day before use by shaking the bottle and then rolling it on a bottle roller to avoid air bubbles in the material as much as possible. After a longer holding time, the material in the vatshould also be homogenized again by mixing.

What has to be considered in case of a misprint?

As a matter of principle, all residues must be removed from the construction platform and from the vat. For the residues in the trough, it is recommended that a short exposure of the entire construction area be carried out so that all residues can be removed at once. Under no circumstances use sharp-edged or metal objects for this, as otherwise the troughs will be damaged. For this, we recommend card sheets made of cardboard (e.g. Rotilabo card sheets from Laborbedarf Roth). In case of major contamination, the material should be filtered.

Publication date: 11-2019/DETAX_R&D3D

Welcome at DETAX online – Your specialists for medical material.

For more than 66 years, we have been developing silicones and light-curing resins for dental and other medical applications. The polymer chemistry of materials is our universe.

Detax. As a brand, this name stands for high-quality medical devices. Since 1954, we have been developing silicones and light-curing resins for dental and other medical applications. The polymer chemistry of materials is our universe. Our enthusiasm and innovative strength is ingrained in every one of the products that you will become familiar on this Website.

read more

We develop hydrophilic impression making silicones for every indication (corrective and double mix technology, kneadable working impression making for functioning rim design, sandwich technology, monophase impression making). Precision impression making materials of lightly flowing consistency with ideal flow characteristics, maximum wetting power, and elastic resilience. Regular set, fast set or super fast set with thermoactive setting characteristics and a defined snap set, kneadable putty, color violet with wildberry flavor. Ear impression making silicones in 50 ml double cartridges specially for IO/CIC changes with lightly flowing starting consistency, even for narrow auditory canals or patients with chronic pain. Ear impression making silicones for children and young people (paediatrics), pressure-less impression, no ingress of soft tissue. Ear impression making material for hearing-protection adjustments, low squeezing pressure, stable, does not run out of the ear, short time in the ear, skin friendly, non adhesive. Highly elastic resilience, easy to remove, 35 Shore A monophase impression making silicone in medium tray consistency. Harmonized consistencies of tray and corrective material. Transfer silicones, quick-setting and clearly transparent A-silicone base bite registration material, medium flow, thixotropic, to be applied directly on the row of teeth, no flowing away into interdental chambers, X-ray transparent matrix material, crystal clear, final hardness 80 Shore A, for light hardening of composites. Scannable VPS bite registration material for the powder-free 3D data acquisition for all CAD/CAM/CIM processes (stripe light projection, laser triangulation and CEREC), 32 Shore D, short time spent in the mouth. Permanently plasticizing relining silicones, direct relining in the dental practice chairside or for processing in the dental laboratory. Broad indication spectrum (obturators and mouth guards) with plaque inhibitors, clinically tested and scientifically documented. Secure bond to prosthetic acrylate. Additional crosslinking duplicating silicones and laboratory plasticines 85 Shore A for precasts, control bites, fixing of artificial teeth, models for prosthetic repairs. Permanently elastic otoplastic silicone, buoyant, direct fitting of water plugs and ear canal plastics, for the indirect manufacture of soft HdO and protective plastics, for PNP, 3D cast technology, permanently keeps its color. Even with extended processing time for series manufacture in the obtoplastics laboratory. Air-drying silicone paint for water plug plastics antibacterial with silver particles. Bis-acrylic composite 10.1 for temporary crowns, bridges and long-term temporaries with elastic phase and maximum and flexural and abrasion resistances, low polymerization temperature, translucent colors: A1, A2, A3, A3,5. Composite-based fissure sealant with wet bonding technology. Protective lacquer for exposed root dentine with high degree of cross-linking based on multifunctional (meth)acrylate has a desensitizing effect, forms a barrier against erosion, thereby reducing cervical sensitivity. Transparent fluoride varnish with amino-fluoride, mouth wash. Flexible gum masks for dental master and saw models, dimensionally stable, for a naturally aesthetic gingival look in tubes or cartridges. Dental cements for definitive and semi-permanent implantation, fasteners, long-term temporary fixing cements, plastic-based radio-opaque, cementation of supra-constructions, dual hardener system. Ready-to-use modeling resin, as a gel or paste, MMA-free, combustible without resins, no polymerization shrinkage. Gum epithesis material, hot curing. Kneable UV plastics for manufacturing biocompatible splints & templates. Plastics for 3D print systems: dentistry models, casting objects, IIa-class clear transparent resins for biocompatible implant templates and splints, KFO (DIN) base parts, long-term temporary K&B composite and supplies in total prosthodontics

© 2020, DETAX Ettlingen, Germany

Video Clip (1:44 Min.)

Video Clip (1:44 Min.)